Exterior Insulation Finishing System

ap Inspections & environmental services inspect the structural component and recommend solutions to fit the client’s needs.

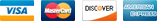

EIFS details are required for water tight or rain screen applications. Wherever EIFS meets another material, backer rod must first be installed in the joint. This keeps caulk from adhering to the back of the joint and allows it to stretch with building movements. A correctly tooled caulk bead has an hourglass shape that is about twice as wide as it is thick.

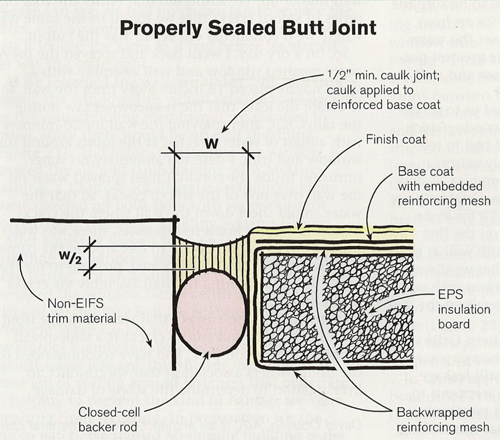

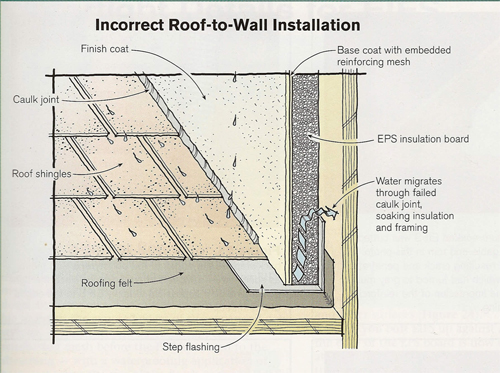

Where EIFS butts directly against the roof (top left), water will wick up into the foam board and eventually make its way past the flashing into the framing. The correct approach is to use a shaped counterflashing above the step flashing (above right). The additional vertical leg creates a ledge for caulk and backer rod, and it keeps the polystyrene board clear of water running along the roof.

Correct Roof to Wall Installation

Incorrect Roof to Wall Installation

Contrary to the manufacturer’s recommendation and common sense, the EIFS applicator butted the edge of the polystyrene directly against the roofing, with no caulk space or counterflashing.

Kick Out Diverter